Services to streamline your process, from design to manufacturing.

Our 45+ years in the medical device ecosystem means we know the most effective, most efficient ways to get past hurdles and improve your device’s time to market.

We help you navigate the whole medical device creation process.

There’s a lot that happens behind the scenes in medical device manufacturing. Quality standards must be met, materials must be delivered on time, devices must be optimized for scale, and a host of other things. Our decades of experience in medical device development and manufacturing ensures there are no surprises along the way. We proactively look at the big picture timeline as well as the minutiae, resulting in better, more efficiently produced devices.

Our Services

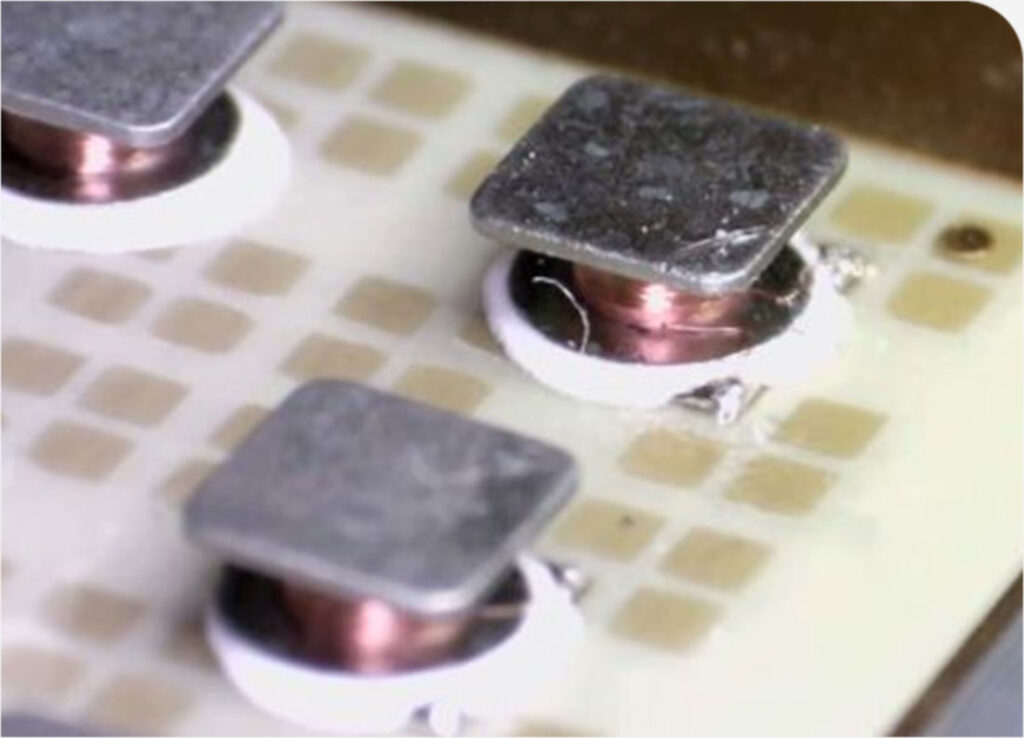

Scalable Manufacturing

We are right-sized for typical medical device volumes. Our size and resources allow high-volume scaling while remaining flexible, responsible and agile.

- Scale to millions and tens of millions

- Strategic global footprint with facilities in U.S. and Asia Pacific

- Three low-cost manufacturing locations for high-volume assembly

Design Control and Regulatory

Our experience managing our own regulatory filings and design history files enables us to accelerate your process. We know the key questions and approaches to drive your projects forward effectively.

- Fully design-control compliant

- Creation of Design History Files (DHF)

- Deep experience with 510(k), PMA and CE Mark submissions

Manufacturing and Tech Transfers

Deep medical device expertise and flexibility in production options leads to better finished products. Whether starting with Intricon or transferring production, we adhere to the same high quality standards.

- Nearly 250,000 sq. ft. of manufacturing space

- Multiple clean rooms

- Facilities in U.S. and Asia Pacific for convenient, low cost

scaling, sourcing and management

Finished Device Packaging

Our final packaging operations ensure package contents are complete and correct. We have available capacity and additional shifts to package, serialize, seal, and ship directly to global distribution centers.

- Automated in-line vision inspection for completeness

- Barcode and visual character recognition components

cross-checked against BOM for configuration control - SFTP (Secure File Transfer Protocol) for Enterprise-to-Enterprise

delivery of technical data relative to shipments

Quality

Everything we produce lives up to rigorous quality standards. Our quality process starts in the development stage to ensure the safest, most dependable products possible.

- ISO 13485:2016

- All Minnesota- and Singapore-based facilities FDA registered

Supply Chain Management

Supply chain delays can add unwanted cost and time to your production timeline. Our deep relationships with high-quality suppliers and trusted logistics partners ensures your projects are finished on time and stay on budget.

- Robust, vertically integrated capabilities eliminate the need for

multiple suppliers - Mitigate risk with consolidated supply chain under one roof